Secondary Processes & Capabilities

Threading, Drilling, Welding, Machining, Close-Attaching, De-burring, Chamfering, Surface Cleaning and more.

Roll Threading

Threading, Knurling and Grooving.

- Max. Thread Diameter- 0.625″ / 15.875mm

- Low Carbon, Stainless, Brass and Copper

Roll threading is a specialized process we use to create strong, precise threads on metal components without cutting the material. Instead of removing metal, we form the threads by rolling the material between dies, which increases the strength and durability of the part. This method is perfect for producing high-quality threads that can withstand heavy loads and wear.

We offer roll threading for a variety of materials, including steel, aluminum, and stainless steel, ensuring accurate and consistent results for every project. Whether you’re looking for custom or standard threads, our roll threading process delivers strong, reliable components that are built to last, making it an ideal choice for applications requiring enhanced thread strength and performance.

Drilling

Multi-Spindle, Single Head Drilling & Tapping

- Plunge up to 8 holes simultaneously

- Round or flat surfaces.

Our drilling services offer precise, clean holes for a wide variety of metal components. Using advanced drilling equipment, we ensure that each hole is accurately placed and sized to meet your exact specifications. Whether you’re working with steel, aluminum, or other metals, we deliver high-quality drilling solutions tailored to your project’s needs.

Drilling is an essential secondary process, perfect for preparing parts for assembly, fastening, or further machining. We handle everything from simple holes to complex drilling patterns, ensuring reliable and consistent results for every part. Whether you need a few pieces or a large production run, our drilling services provide the accuracy and quality you require.

Finishing Touches

Welding, Machining, De-burring, Chamfering, Close-Attaching, Heat Treating and Cleaning

Complex Parts and Assemblies sometimes require additional forming and/or processing operations that make them meet all critical attributes and specifications, as quoted.

Our Finishing Touch services are designed to give your metal components a polished, professional look and enhanced durability. Whether it’s smoothing rough edges, applying protective coatings, or adding surface treatments, we ensure each part is refined to meet your specific requirements.

These finishing processes not only improve the appearance but also increase the lifespan and functionality of your components. From deburring and polishing to coating and painting, we tailor our finishing touches to suit the needs of your project, ensuring your parts are both visually appealing and ready for demanding applications. Our attention to detail in finishing ensures that your products stand out with superior quality and performance.

Industries / Part Types

Here are some of the types of parts we make for OEMs in their respective industries:

- Armrest Rods & Latches

- Battery Bolts ( J Bolts )

- Battery Hold Down Kits

- Bed Attachment V-Hangers

- Cargo D-Ring Assemblies

- Crash Rods

- Exhaust Hangers

- Glovebox Latch Wires

- Headrest Wires

- Hood Latch Wires

- Hub Retainer Wire

- Isofix Wires

- Luggage / Cargo Tie-down

- Pencil Braces

- Rod Mounting Brackets

- Seat Anchors

- Seat Belt Links

- Seat Frame Wires & Assemblies

- Seatback Fasteners

- Strikers (Collared)

- Drilled J-Hooks (up to 5/8″ dia.)

- Drawbars (Stainless, Carbon and Chrome Vanadium)

- Cupwashers (Flat Top, 4-Lobe, Witches Hat)

- Hitch Pins

- Compression Springs (Conical or Linear)

- Double-D Handles

- Cage Clips

- Drilled Flat Hook Adjust Bars

- Chain (Stainless, Zinc or Alloy)

- Adjuster Rods

- Arm Releases

- Brake Rods

- Crank Rods

- Feeder Rods

- Gate Rods

- Grab Rails & Handles

- Heavy Duty Fasteners

- Latch Assemblies

- Lift Assist Arms

- Pen Hardware & Fasteners

- Shift Rods

- Tie-Down Assemblies

- Torsion Rods

- Shift Rods

- Brake Rods

- Seat Wires

- Lift Brackets

- Hold-down Rod Assemblies

- Bag Frames

- Adjuster Rods

- Cultivator Shafts

- Welded Cultivators

- Prop Rods

- Shift Rods

- Handles

- Lock Pins

Power & Communication Line Hardware

This is just a sample of what we do. We manufacture parts for many other OEMs and Industries.

Engineering Support

Quality Planning. Tooling Design. Development. PPAP to Production.

Our Commitment is to do everything we can to help you Win.

Are you Looking for...

General Chain & Mfg. Corp. has two main divisions:

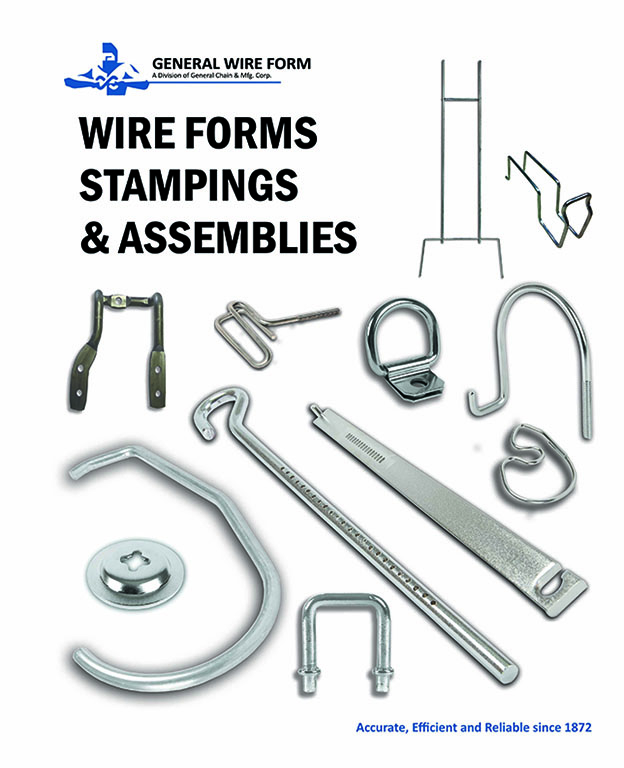

- Manufacturing Wire Forms, Metal Stamping & Assemblies

- Chain & Accessories