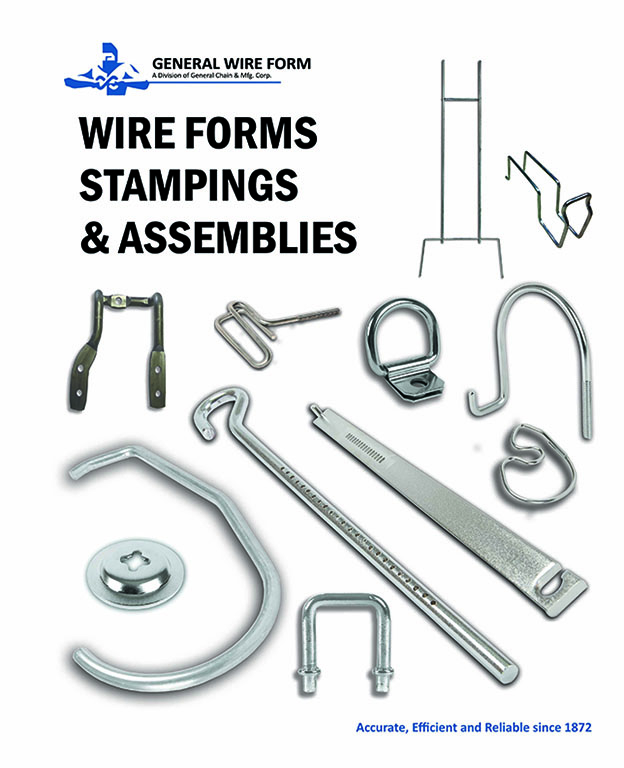

Metal Stampings

Blanking

Progressive Die Forming

Secondary Die Forming

Swaging & Profiling

Metal Stamping is an essential process for creating precise metal parts and components. We design and deploy high-quality forming and finishing dies for our diverse line of presses. Whether your part specifications are simple or complex, our metal stamping services deliver accuracy and durability.

Ideal for high-volume production. From small components to large metal pieces, we focus on providing efficient, cost-effective solutions for all your stamping needs.

Materials: Carbon Steel, Stainless Steel and Galvanized Steel

Blanking

Trimming & Blanking

- Presses up to 600 Tons

- Design & Build Dies

Blanking is a precise metal stamping process where we cut flat shapes from sheet metal, creating clean, accurate parts that match your specifications. Using high-quality dies and advanced presses, we ensure that each piece is cut with precision.

- A cost-effective way to produce metal parts with smooth edges, ready for further processing or use in your project. Whether you need simple blanks or more complex forms, our blanking services offer reliable, high-quality results.

Progressive Die Stamping

Extensive Design & Build Experience

- Design and Build Dies

- Stock Width up to 12 inches

- Presses up to 600 Tons

Progressive Die Stamping is an efficient method for producing complex metal parts in a continuous process. Using a series of stations within a single die, we shape and cut metal sheets step by step, ensuring precision and consistency in every part. This process is ideal for high-volume production, delivering multiple components quickly and accurately.

- Ideal for creating detailed, intricate designs while maintaining cost-effectiveness. Whether you need small or large production runs, this method ensures high-quality parts with minimal waste and reduced production time.

Secondary Die Forming

Swaging & Profiling. Pierce & Trim.

- Design & Build Dies

- Presses up to 600 Tons

Secondary Die Forming is used to refine and add additional shapes or details to metal parts after the initial stamping process. This group of forming / finishing processes allows us to take pre-formed metal pieces and apply more intricate bends, cuts, or shapes, ensuring your parts meet precise specifications.

We handle a variety of metals like Carbon and Stainless steel, making sure that each piece is shaped accurately and consistently. Secondary die forming is ideal for projects that require more detailed work or adjustments after primary forming, ensuring that your final parts are perfectly finished and ready for use in any application.

Swaging & Profiling

Swaging and profiling are specialized metal shaping processes used to form precise shapes and profiles in metal parts. Swaging involves compressing and shaping metal without removing material, allowing us to create tapered or contoured sections. Profiling, on the other hand, helps to refine the metal’s edges and surfaces, ensuring smooth, consistent forms that meet your exact specifications.

Both swaging and profiling can be applied to various materials, including steel, aluminum, and copper, to produce high-quality parts with enhanced detail and accuracy. These methods are ideal for industries requiring custom shapes and detailed metal components, offering a reliable solution for producing strong and durable metal forms tailored to your project’s needs.

Engineering Support

Quality Planning, Tooling Design, Development and From PPAP to Production.

Our Commitment is to do everything we can to help you Win.

Industries / Part Types

Here are some of the types of parts we make for OEMs in their respective industries:

- Armrest Rods & Latches

- Battery Bolts ( J Bolts )

- Battery Hold Down Kits

- Bed Attachment V-Hangers

- Cargo D-Ring Assemblies

- Crash Rods

- Exhaust Hangers

- Glovebox Latch Wires

- Headrest Wires

- Hood Latch Wires

- Hub Retainer Wire

- Isofix Wires

- Luggage / Cargo Tie-down

- Pencil Braces

- Rod Mounting Brackets

- Seat Anchors

- Seat Belt Links

- Seat Frame Wires & Assemblies

- Seatback Fasteners

- Strikers (Collared)

- Drilled J-Hooks (up to 5/8″ dia.)

- Drawbars (Stainless, Carbon and Chrome Vanadium)

- Cupwashers (Flat Top, 4-Lobe, Witches Hat)

- Hitch Pins

- Compression Springs (Conical or Linear)

- Double-D Handles

- Cage Clips

- Drilled Flat Hook Adjust Bars

- Chain (Stainless, Zinc or Alloy)

- Adjuster Rods

- Arm Releases

- Brake Rods

- Crank Rods

- Feeder Rods

- Gate Rods

- Grab Rails & Handles

- Heavy Duty Fasteners

- Latch Assemblies

- Lift Assist Arms

- Pen Hardware & Fasteners

- Shift Rods

- Tie-Down Assemblies

- Torsion Rods

- Shift Rods

- Brake Rods

- Seat Wires

- Lift Brackets

- Hold-down Rod Assemblies

- Bag Frames

- Adjuster Rods

- Cultivator Shafts

- Welded Cultivators

- Prop Rods

- Shift Rods

- Handles

- Lock Pins

Power & Communication Line Hardware

This is just a sample of what we do. We manufacture parts for many other OEMs and Industries.

Are you Looking for...

General Chain & Mfg. Corp. has two main divisions:

- Manufacturing Wire Forms, Metal Stamping & Assemblies

- Chain & Accessories

Metal Stampings Manufactured in Cincinnati

At our Cincinnati-based facility, we specialize in providing high-quality metal stampings for a variety of industries. Whether you need precision components for automotive, aerospace, or industrial applications, we’ve got you covered. We use advanced stamping techniques and state-of-the-art equipment to produce metal parts that meet your exact specifications.

Our team focuses on delivering durable and accurate stampings, ensuring each piece matches your design requirements. We work closely with you from the design phase through production, providing custom metal stampings that fit your project’s needs. If you’re looking for reliable metal stamping services in Cincinnati, we’re here to offer expert solutions with a commitment to quality and timely delivery.

Commercial Metal Stampings

We specialize in producing high-quality commercial metal stampings for a wide range of industries, including automotive, construction, electronics, and more. Our team uses advanced techniques and top-grade materials to create metal components that meet the strictest standards for durability and precision.

Whether you need small, intricate parts or larger, heavy-duty components, we can customize our stamping solutions to fit your exact requirements. We work closely with our clients to ensure every part is crafted to their specifications, providing reliable, cost-effective metal stampings for commercial applications. With our expertise and commitment to quality, we’re the trusted partner for all your commercial metal stamping needs.

Sheet Metal Stamping for Agricultural Equipment

We specialize in agriculture sheet metal stamping, providing durable and precise metal components for the agricultural industry. Our expertise allows us to produce high-quality parts, from tractor components to equipment housings, that are designed to withstand the demands of tough farming environments.

Using advanced stamping techniques, we ensure that each piece is crafted to meet your specific requirements. Whether you need custom parts or large production runs, we deliver reliable and long-lasting solutions. Our team works closely with you to ensure that our agricultural metal stampings enhance the performance and durability of your equipment. With a focus on quality and precision, we’re your go-to partner for agriculture sheet metal stamping needs.